If you’ve worked with LED lighting anytime in the last few years, you’ve probably noticed something: those little orange levers are everywhere.

Open up a fixture, a control box, or a retrofit kit, and chances are you’ll find a WAGO connector staring back at you.

Electricians love them. OEMs spec them. DIYers swear by them once they try them.

So what’s the big deal?

This guide breaks down why WAGO connectors have become the go-to wiring solution, how the different styles compare, and how to choose the right one for your lighting project – whether you’re swapping an LED driver or wiring an entire system.

Why WAGO Has Become the Installer Favorite

WAGO didn’t just improve wire connectors – they rethought how electrical connections should work.

Instead of relying on screws that loosen over time or twist-on connectors that depend on installer technique, WAGO uses spring pressure to maintain a consistent, long-term connection.

A few reasons that matters (especially for LED lighting):

No tools required – open the lever, insert the wire, close it

Reusable – perfect for testing, troubleshooting, or future changes

Vibration-resistant – connections stay solid over time

Finger-safe design – no exposed live metal

Clear housing – visually confirm proper strip length and insertion

Built-in test ports – easy multimeter access without disconnecting wires

Add in UL listing, plus CE and IEC approvals, and you get a connector that works just as well in a residential cabinet as it does in a commercial control panel.

A Little WAGO History (and Why It Matters)

WAGO didn’t jump on a trend – they created one.

Back in the 1970s, WAGO invented the cage clamp (spring clamp) connector, replacing screw terminals that were prone to loosening, corrosion, and inconsistent torque. Today, that same concept is refined into the lever and push-in connectors you see everywhere.

Why spring clamp technology is more reliable:

- Constant pressure on the conductor

- No relaxation over time (unlike screws)

- Excellent vibration resistance

- Works with solid, stranded, and fine-stranded wire

This is also why so many manufacturers have tried to copy the design.

WAGO Lever Connectors (aka “Lever-Nuts”)

These are the connectors most people think of when they hear “WAGO.”

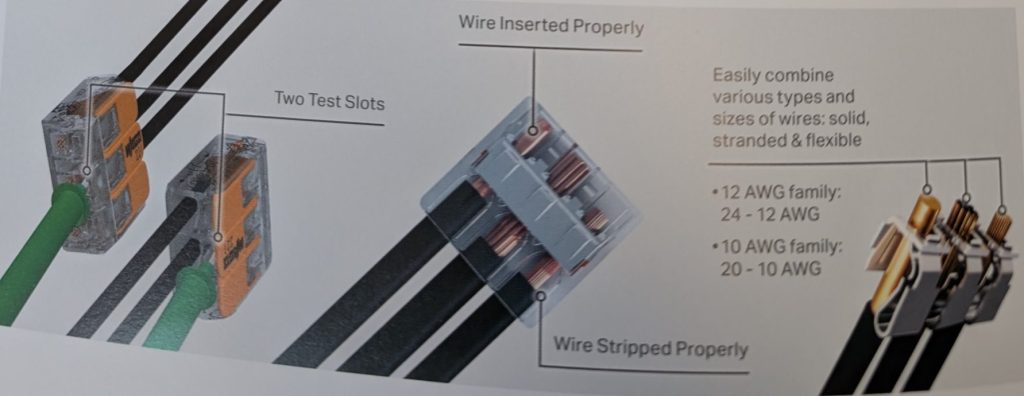

The 221 Series Lever-Nuts combine ease of use with serious electrical performance, making them ideal for LED applications.

Why Lever-Nuts Are So Popular

- Wide wire gauge range (including fine-stranded wire)

- Accept solid, stranded, and flexible conductors

- Tool-free operation

- Reopen and reuse as many times as needed

Just lift the lever, insert the stripped wire, and close it. That’s it.

Thanks to the transparent housing, you can immediately verify:

- Correct strip length

- Full conductor insertion

- Proper seating of the wire

What’s Inside the Connector?

Inside each connector is a tin-plated copper spring clamp. This does two important things:

- Bonds cleanly with copper conductors

- Creates an airtight connection, which helps prevent corrosion over time

In destructive testing, WAGO has shown that the surrounding materials fail before the metal connection does – a strong testament to the reliability of the clamp itself.

Push-In WAGO Connectors: When Simple Is Best

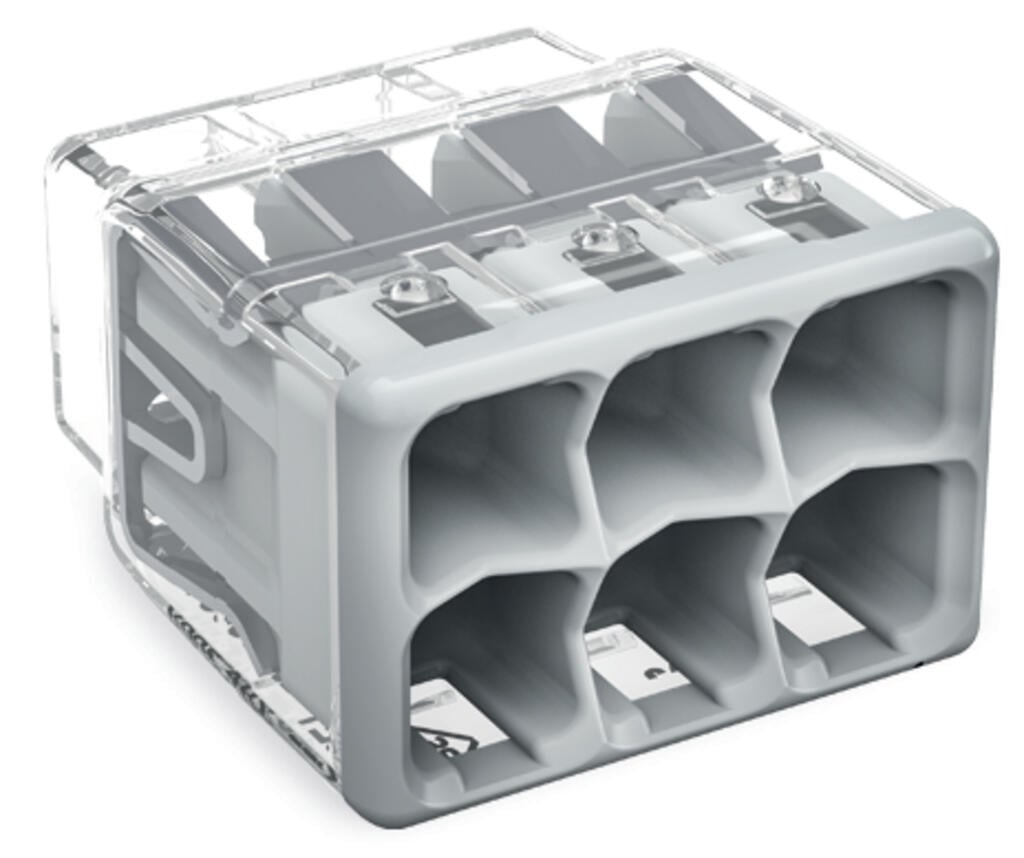

While lever connectors get most of the attention, push-in 2773 WAGO connectors are still a great choice for the right application.

These are ideal when:

- The connection is permanent

- Space is extremely limited

- You’re doing high-volume or repetitive wiring

Push-in connectors are smaller and faster for production work, but they aren’t designed to be reopened repeatedly. If you don’t anticipate future changes, they’re an excellent option.

WAGO Luminaire Disconnects: Clean, Code-Friendly Lighting Connections

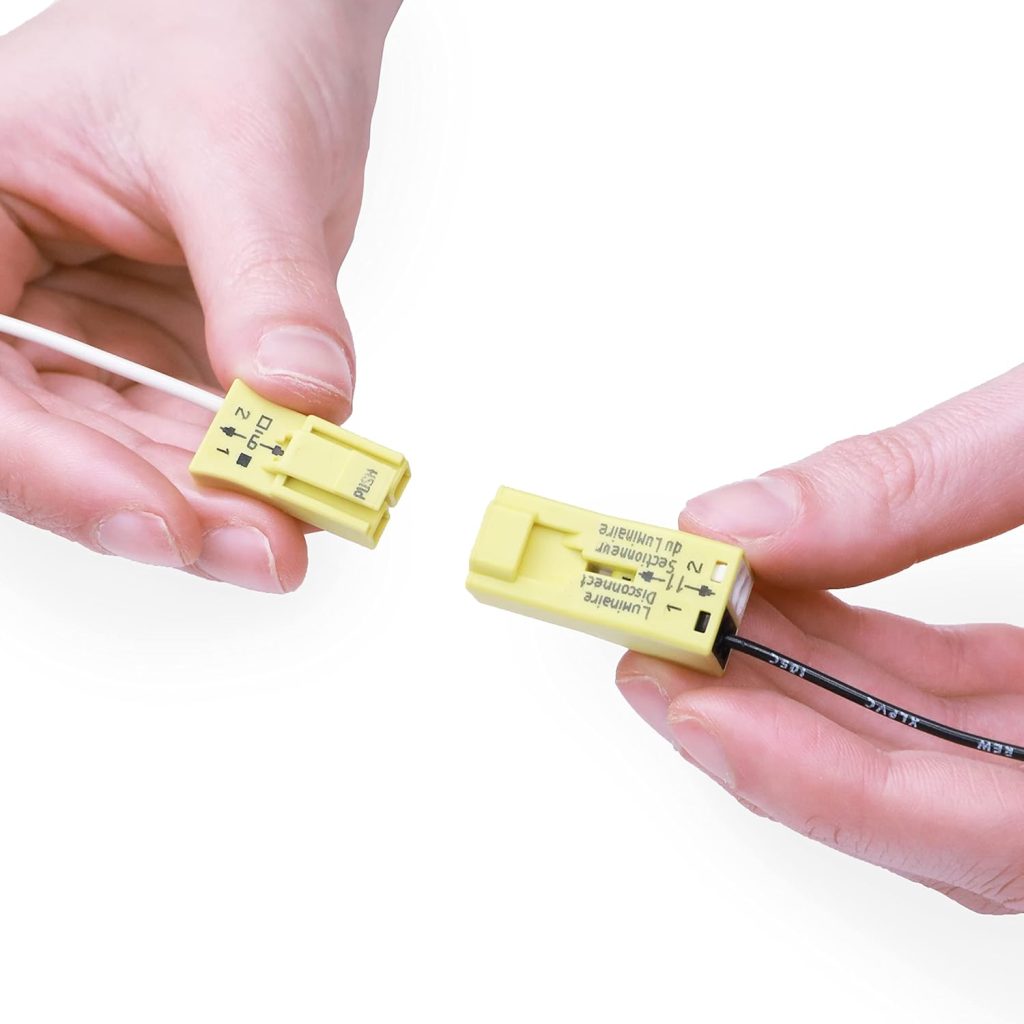

If you’ve worked with modern lighting fixtures, you’ve probably seen the 8773 series luminaire disconnects becoming more common – and for good reason.

A luminaire disconnect allows a fixture to be:

- Safely disconnected from power

- Serviced or replaced without disturbing permanent wiring

- Brought into compliance with modern electrical codes

WAGO luminaire disconnects are commonly used in:

- LED panels

- Downlights

- Retrofit kits

- Hardwired fixtures

They’re compact, tool-free, and purpose-built for lighting applications – making them a clean solution inside tight fixture housings

Which WAGO Connector Should You Use?

Need flexibility or future changes? → Lever-Nuts

Need the smallest possible connector for a permanent install? → Push-In

Working with fixtures or code-driven installs? → Luminaire Disconnects

When in doubt, lever connectors are usually the safest bet – especially for LED systems where changes happen more often than expected.

Common Mistakes to Avoid (Even With Great Connectors)

Even the best connector can fail if installed incorrectly. A few tips:

- Don’t over-strip the wire (use the strip length marking)

- Make sure stranded wire is fully inserted

- Always perform a light pull test

- Use mounting accessories when strain relief is needed

The clear housing makes it easy to spot issues before they become problems.

Final Thoughts: Why WAGO Is Worth the Upgrade

WAGO connectors aren’t just about convenience – they’re about consistency, safety, and long-term reliability.

If you’ve ever dealt with loose connections, cramped wiring, or future rework headaches, switching to WAGO is one of those upgrades you only regret not making sooner.

👉 Explore WAGO connectors and accessories available at LEDSupply and see why so many lighting professionals have already made the switch.